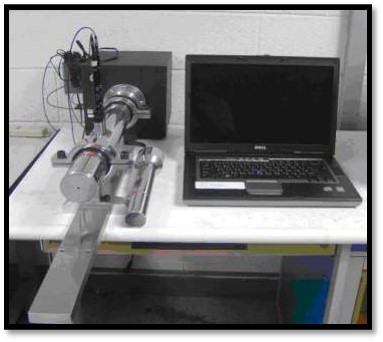

1. Normal incidence sound absorption coefficient Measurement system (ASTM E1090):

This system uses professionally designed normal incidence testing equipment, acoustic barrier tubes, and measuring the sound absorption coefficient of materials or products. This method is usually used for quick testing, with high testing efficiency and relatively low production costs.

2. Random Incident Sound Absorption Coefficient Measurement System(ASTM C423):

This is a measurement method carried out in a reverberation chamber. In principle, The sound waves are transmitted through the material being measured to measure the amount of sound lost as it propagates through the material. This loss can be caused by a variety of factors, including material structure, density, thickness, etc. Through measurement loss, we can evaluate the sound absorption capacity of different materials and understand the merits and demerits of their sound absorption performance. The test area is 10~12m2, and the pipe test structure is comparatively high, but this method can provide a more accurate sound absorption performance evaluation.

3.Transmission loss measurement system:

This method measures the sound loss through a material and evaluates its sound absorption performance. Our system is equipped with advanced testing equipment, enabling accurate evaluation of the sound absorption capacity of materials.

Mechanical performance evaluation is an important step to ensure products have sufficient strength and durability in various application situations. The following are commonly used methods for evaluating mechanical properties:

1. TD-500 compression tester:

This is a widely used tool for evaluating the mechanical properties of materials, such as stretching and compression. Facilities. Through the application of different strengths, we can evaluate materials' tensile strength, yield strength, elastic modulus and other important parameters to ensure the strength and stability of products.

2. TD-SW320 Flame Resistance Tester:

This is a specialized equipment for evaluating the fire resistance of materials. By placing the materials in a high temperature environment, we can evaluate their fire resistance to ensure that products have sufficient fire resistance in the event of a fire, thereby protecting people's lives and property safety.

3. TD-EN200M cooking cabinet:

This is a device that uses materials to simulate the performance of high-temperature environments. By placing materials in a high temperature environment and undergoing thermal aging tests, we can evaluate their performance changes during long-term use to ensure the durability and usability of products.

Through these dynamic performance evaluation methods, we can comprehensively evaluate the dynamic performance of our products, ensure that they can perform outstandingly in various application situations, and satisfy customers' demands and expectations.

SanShiang Tainan Factory

SanShiang Taoyuan Factory

PAGE TOP

PAGE TOP

We use cookies to collect and analyze information on site performance and usage. By Clicking "Continue" or by clicking into any content on this site, you agree to allow cookies to be placed. To find out more, please visit our privacy policy。

CONFIRM